Main Spindle & Sub Spindle Collets

Main & Spindle Collet: Our Main and Sub-Spindle Collets for CNC sliding head machines are engineered for high-precision and reliable performance. These collets provide superior grip and alignment, ensuring efficient machining of complex parts in high-speed operations.

Key Features

- High-Precision Clamping: Ensures stable bar holding and concentricity.

- Durable Materials: Made from hardened steel or carbide for extended lifespan.

- Customizable Sizes: Available in standard and custom configurations.

- Versatile Applications: Suitable for diverse machining needs in automotive, aerospace, and medical sectors.

- These collets are the ideal choice for achieving unmatched efficiency and accuracy in CNC sliding head operations.

Long Nose Collet: Specifically when utilizing right-handed parting off tools, collets with longer noses (Long Nose) enable the sub-spindle to clamp tiny diameter thin components. They are especially helpful for supporting lengthy components when the tool holder design limits clearance.

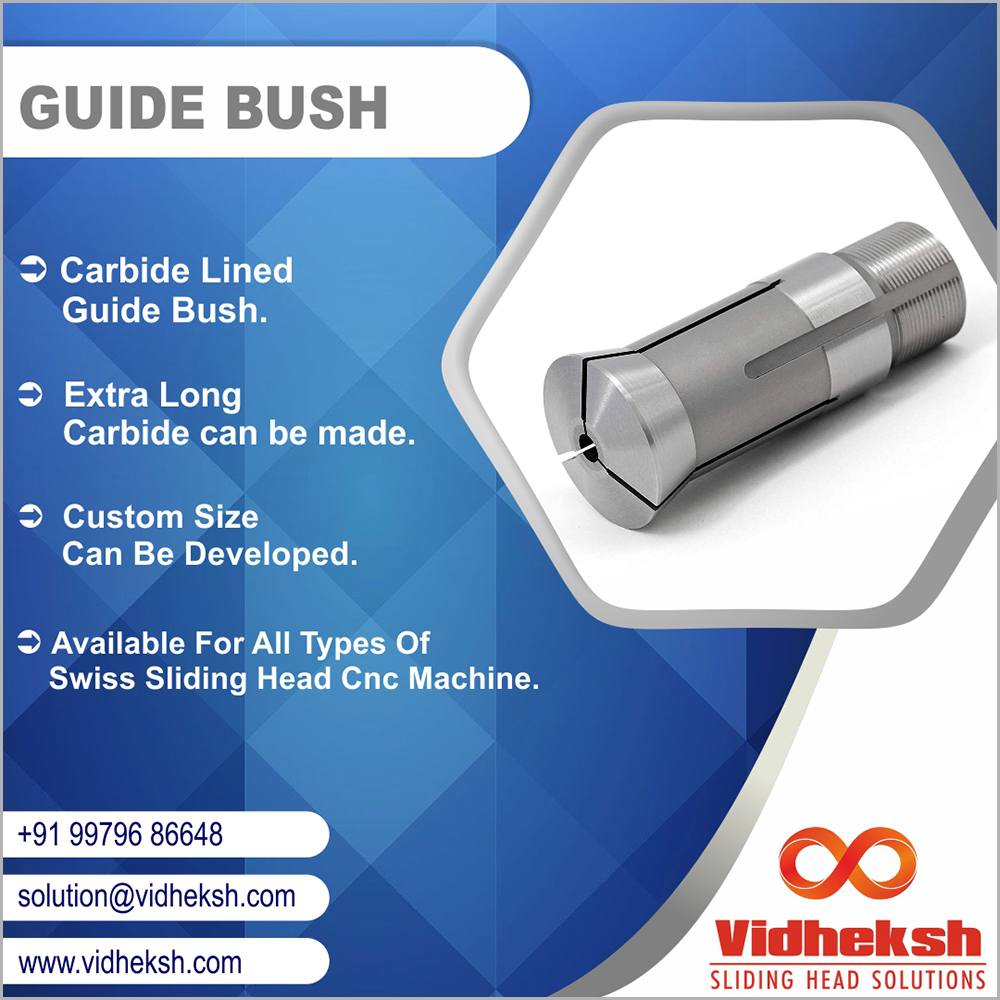

Guide Bush

Our Carbide-Lined Guide Bushes are precision-engineered for sliding head CNC machines to deliver superior performance and durability. Designed with high-quality carbide lining, these guide bushes offer enhanced wear resistance and maintain precision during high-speed machining operations.

Key Features

- Enhanced Durability: Carbide lining ensures prolonged tool life.

- High Precision: Maintains concentricity and accuracy during machining.

- Vibration Reduction: Facilitates smooth bar rotation and stability.

- Customizable Sizes: Tailored to fit various machine models.

- Ideal for high-precision industries such as aerospace, automotive, and medical equipment manufacturing, our guide bushes provide unmatched reliability and efficiency.

Finger Chuck

Our Feed Finger Chucks are designed specifically for sliding head CNC machines, ensuring optimal performance in bar feeding operations. Precision-engineered with robust materials, these chucks guarantee reliability and efficiency during high-speed machining.

Key Features

- Durable Construction: Built to withstand extensive use and heavy loads.

- Precision Grip: Provides stable and secure bar feeding for accuracy.

- Custom Fit: Available in various sizes to match specific machine requirements.

- Ease of Use: Designed for quick installation and minimal maintenance.

- These chucks are ideal for high-volume production, delivering consistent and flawless results across diverse industries.

Bar feeder collets are used with automatic barfeeders manufactured by Fedek, Iemca, Barload, Tornos, and other companies. The Swiss type CNC machines are the primary equipment that use these bar feeders to feed the rods. The raw material bar's end is held in place and spins together with it by the Barfeeder Chuck, also known as the Finger Chuck. The rods are held under spring tension by simply pushing them into the Barfeeder collet, which is already crimped. As a result, the Bar feeder collets' mechanical springing quality is crucial.

Barfeeder collets come in three different varieties: External Thread, Internal Thread, and Pin Type. Every chuck is given in accordance with the requirements of the bar feeder manufacturer and offers a range of holding capacities.

Thread Whirling Holders

"Thread whirling" has become a popular process for Swiss machines, especially among bone screw manufacturers. Although most Swiss machine engineers agree that thread whirling delivers outstanding productivity with the highest efficiency vs conventional single point threading, not all engineers know the "Real Thread Whirling" process.

A quick and precise method for Long Parts threading, small-diameter components made of exotic materials like titanium and nickel-based alloys is thread whirling. When employed on Swiss-type machines, our series of thread whirling tools allows the manufacture of lengthy, small-diameter threads.

A vast array of medical components, including dental implants and bone screws, as well as automotive and semiconductor sector tiny parts, may be produced using whirling inserts and holders.

Qualities: Enhanced productivity: Thread Whirling reduces machining times by operating under high feed rates and is completed in a single pass.

Extremely high geometry accuracy and surface quality: Burr-free top-quality surfaces are generated by utilizing numerous cutting edges, excellent concentricity, and optimal chip removal.

Longer tool life: Because whirling spindle rotation is used to accomplish cutter side clearance (rather than relieving material under the cutting edge), whirling inserts have a stronger cutting edge than single-point tools.

Faster setup: Thread whirling lowers early R&D expenditures by doing away with the requirement for specialized support devices.

Support for big helix angles: The whirling unit may be adjusted to cater for large helix angles.

Key Features

- High-Precision Performance: Delivers accurate and consistent thread profiles.

- Robust Construction: Made with durable materials for extended tool life.

- Efficient Operation: Reduces cycle times for high-speed production.

- Versatile Design: Compatible with a variety of thread pitches and profiles.

- Perfect for industries such as automotive, aerospace, and medical devices, our thread whirling attachments ensure reliable and efficient thread machining.

Threading Inserts

We are supplier of Custom design threading Carbide Inserts. Carbide Inserts are replaceable and generally indexable bits of solidified carbide utilized in machining prepares, cast iron, high temperature alloys, and nonferrous materials. Carbide Inserts permit quicker machining and leave better completes on metal parts.

Carbide profile insert is customized form insert according to require cutting profile as per component. Profile insert is used to finish multiple dimensions in single plug with single insert by turning or milling operation

Due to profile inserts component can finish in single cut results into less cycle time.

Increase productivity and reduce cost per component as well as tooling cost also.

Profile inserts are available in carbide or high speed steel material with different coating according to the component material.

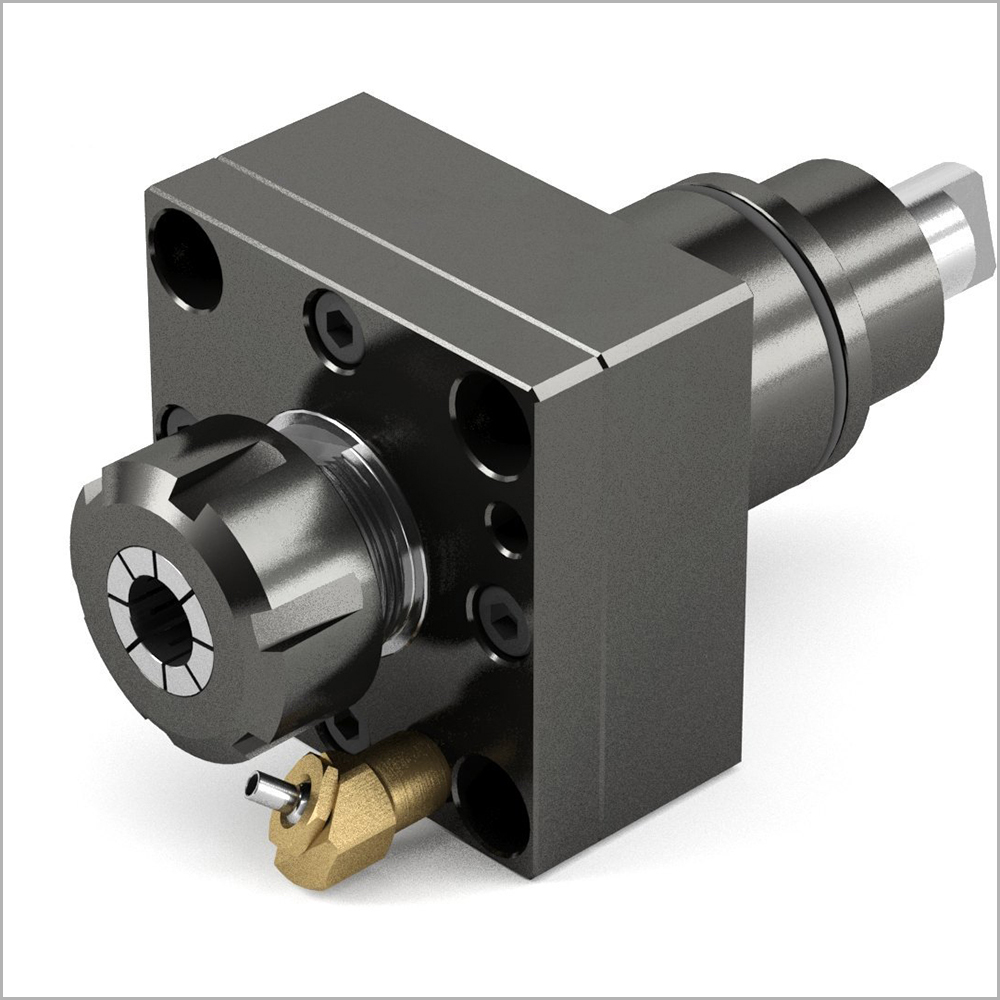

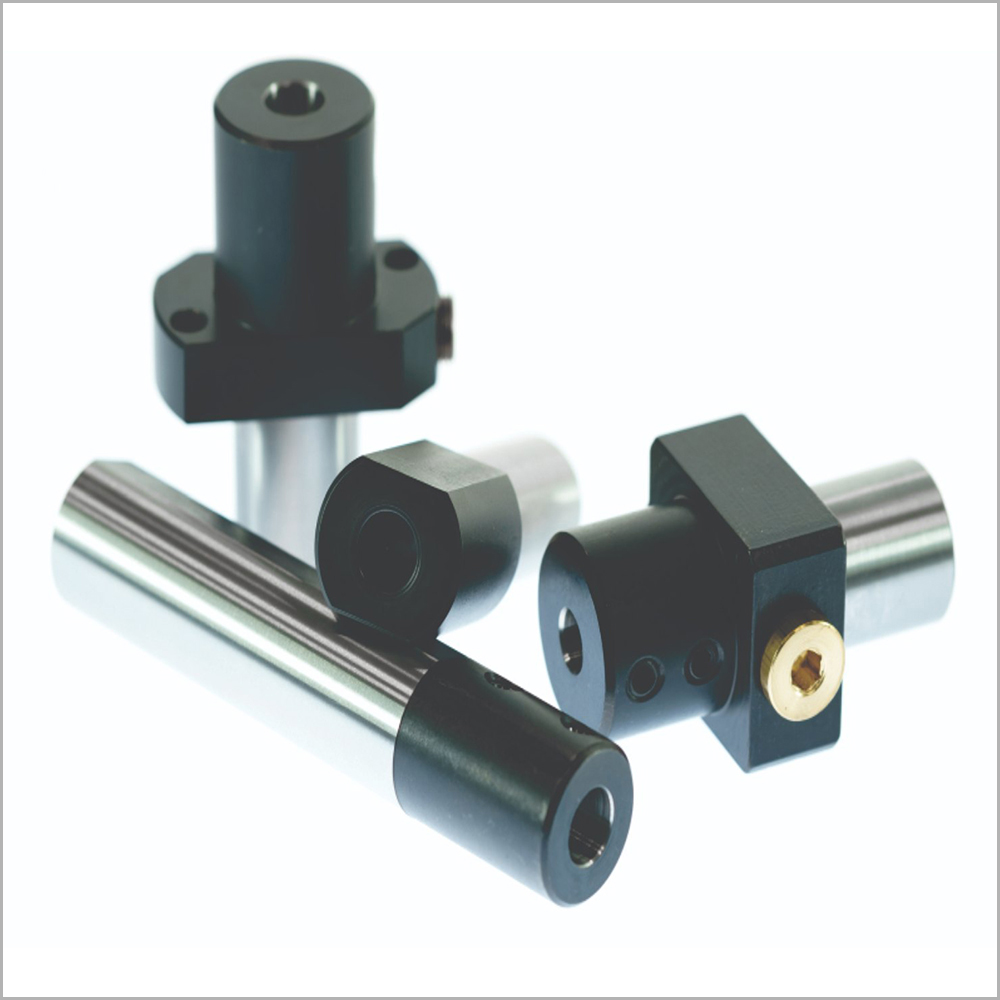

Live Tool Holders

Our Live/Driven Tool Holders are designed for CNC sliding head machines, enabling high-performance machining with superior precision. These tool holders allow for the efficient execution of milling, drilling, and tapping operations on complex components, ensuring optimal productivity.

We provide Live / Driven Tool Holders in various sizes and styles to suit your CNC Sliding head Machine to do your complex job machining operations. Our Holders provide optimal gripping power and vibration dampening while featuring a built-in dust shield to protect against chips and debris.

Live / Driven tool holder is made from high-quality materials for durability and long-lasting performance. Choose from straight, dovetails, or universal styles in various sizes to find the perfect fit for your CNC Sliding Head machine.

Machine Make : Tornos, Hanwha, Tsugami, Citizen, Star, Nomura etc

Key Features

- High Precision: Ensures stable and accurate tool rotation for intricate machining tasks.

- Robust Construction: Manufactured using durable materials for extended life under high-speed conditions.

- Flexible Configurations: Compatible with various machine brands and models.

- Increased Efficiency: Reduces tool change times, enhancing overall productivity.

- These tool holders are ideal for industries demanding high precision, such as aerospace, medical, and automotive sectors.

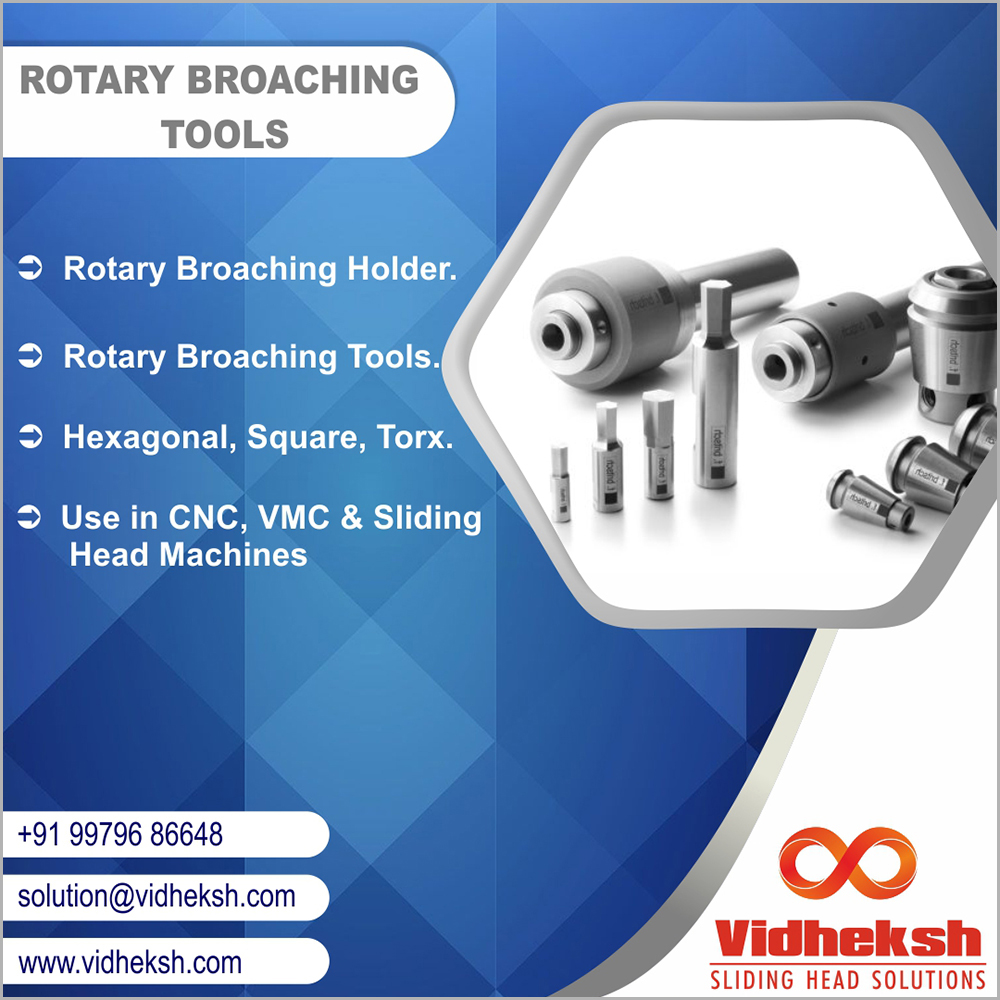

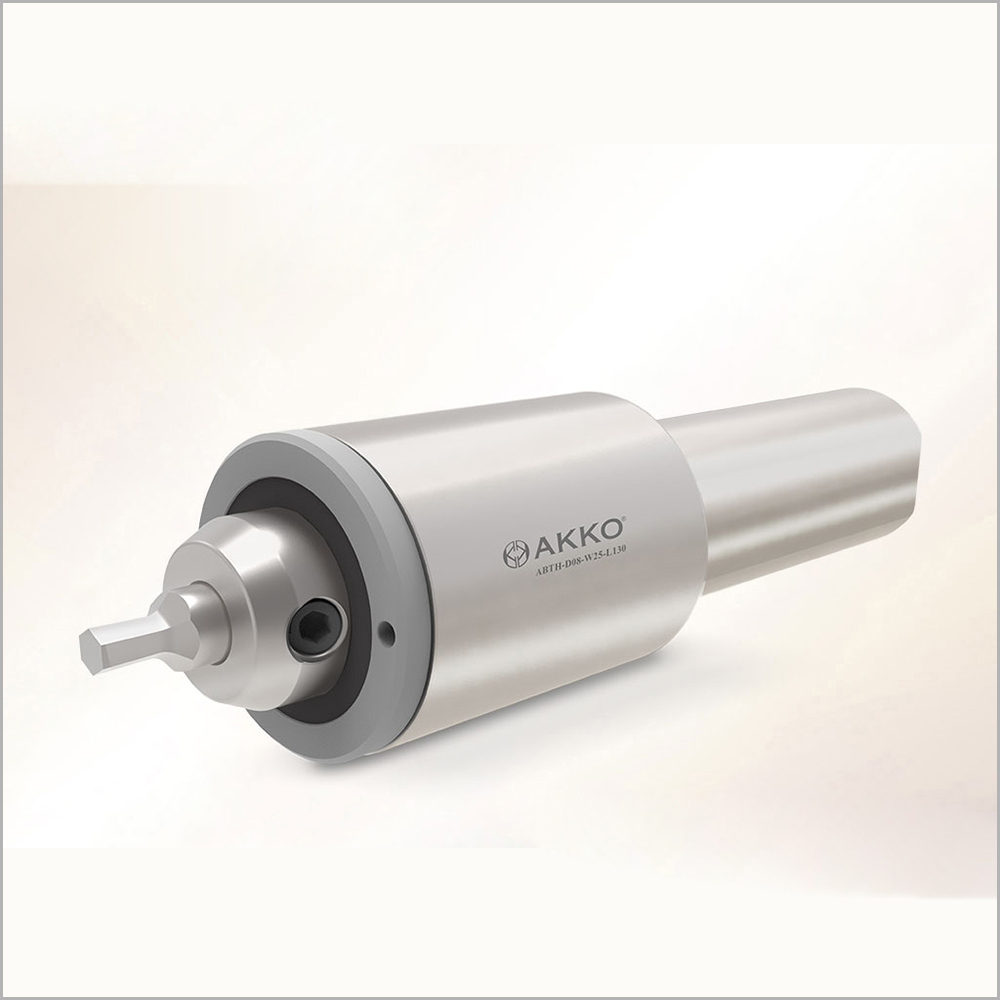

Hex / Torx Rotary Broaching tool

Our Rototech Rotary Broaching Tool Holder with premium quality advanced bearing design. Tool holder’s compact design reduces the tooling envelope, and is the most practical design for compact size machines. Broaching standard size hex and square forms is possible due to the high quality bearings. Its adjustment free design for extremely fast and easy set-up.

In ROTARY BROACHING operation, the broach is rotated and pressed into the workpiece to cut a desired shape and size like square, hex etc... A rotary broach is used in a CNC lathe, VMC or in Sliding Head Machine. In this processes the cut is performed in one pass of the broach, which makes it very efficient. It is very cost effective, highly productive and maintenance free tool.

Key Features

- Extremely Quick and Accurate.

- No Secondary Operations Required.

- Adjustment-Free for Minimal Set-Up Time.

- Relatively Inexpensive Tooling.

- Works on Any CNC Lathe, VMC or Sliding Head Machine.

- Great Finish Quality.

- Reduces Machining Time = Greater Profits

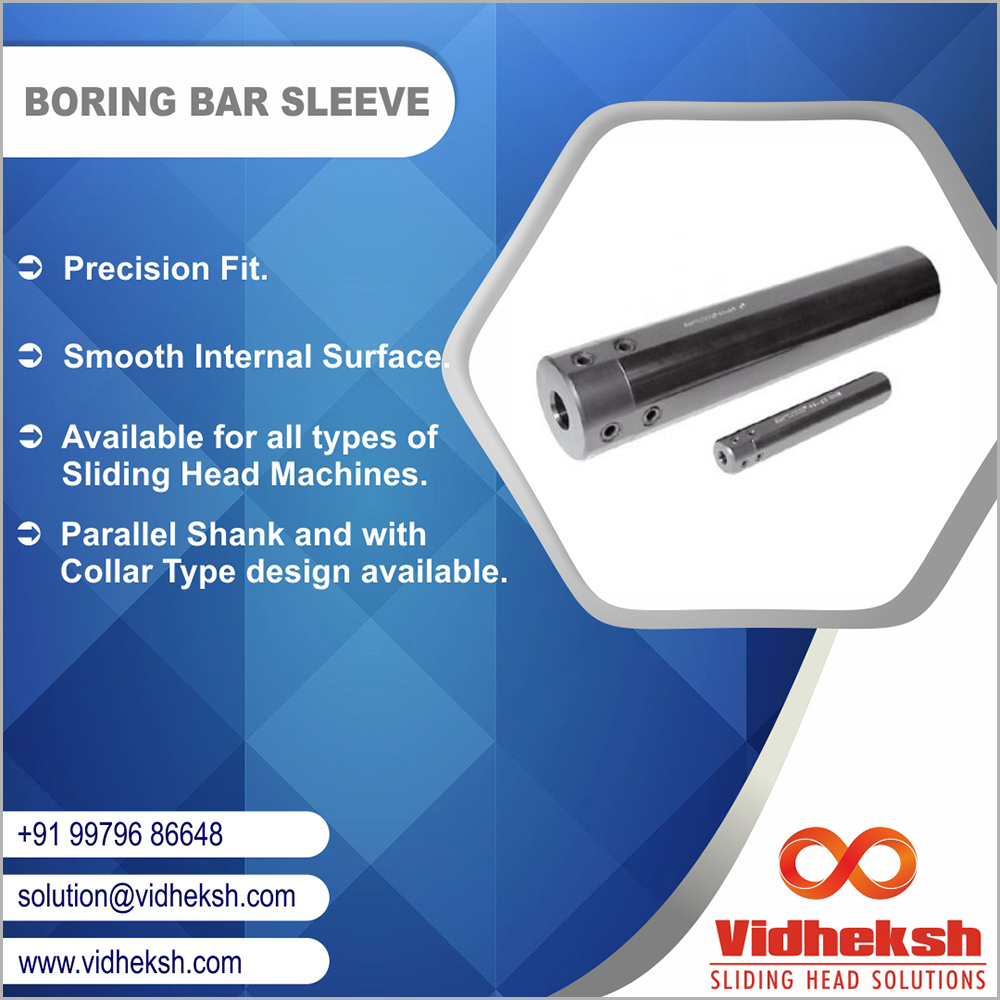

Boring Bar Sleeves

Our Micro Boring Bar Sleeves are specifically designed for CNC sliding head machines, providing precision and stability for micro-boring applications. These sleeves ensure optimal tool holding and alignment, enhancing machining accuracy even for the smallest components.

Boring bar sleeves are used to securely hold boring bars or micro tools in CNC sliding head machine to perform as a sub spindle side operations. They ensure precision and stability during internal machining processes such as boring, threading, or reaming. The sleeves help reduce tool vibration and maintain concentricity.

We provide boring bar sleeves for all types of CNC sliding head machine. We provide collar-style and parallel shank boring bar sleeves. To guarantee the best quality and long lifespan, each of our sleeves is meticulously machined from alloy steel, heat treated, and ground.

Key Features

- Precision Fit: Ensures secure clamping for micro tools.

- High Durability: Constructed from hardened steel or carbide for extended life.

- Compact Design: Ideal for tight spaces and intricate machining operations.

- Versatile Compatibility: Suitable for various tool sizes and machine models.

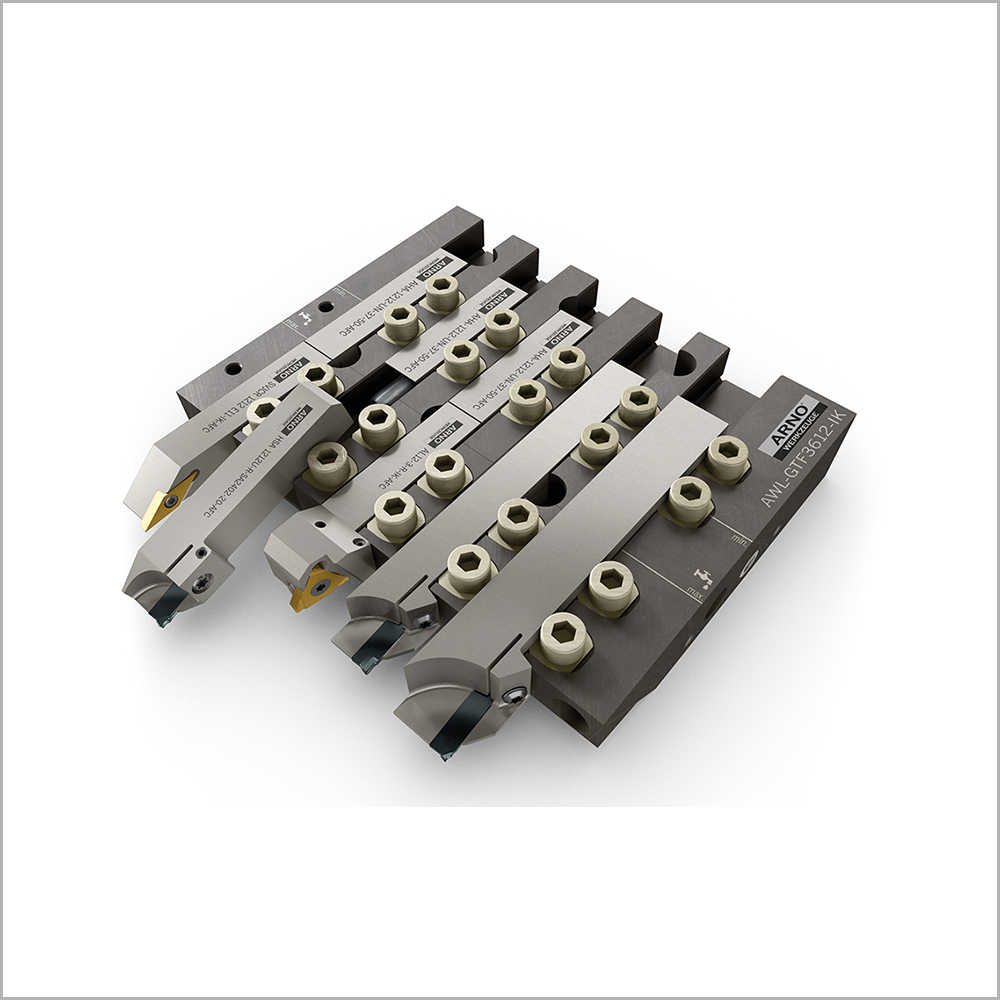

Turning, Parting Holders & Inserts

Turning Tool holders and Inserts: Our Turning Tool Holders and Inserts are specifically designed for CNC sliding head machines, ensuring high precision and durability for turning, profiling, and finishing operations. These tools enhance efficiency in machining complex parts with tight tolerances.

Key Features

- Precision Design: Ensures stable and accurate tool positioning.

- Premium Inserts: Available in various grades for materials like steel, stainless steel, and titanium.

- Durable Construction: Robust materials for extended life under high-speed conditions.

- Custom Solutions: Tailored holders and inserts for specific applications.

- Ideal for industries like automotive, aerospace, and medical.

Back Turning Tool Holder: Our Back Turning Tool Holders and Inserts are engineered for CNC sliding head machines, specifically designed for precision back-turning operations. These tools ensure efficient and accurate machining of complex components with challenging geometries.

Key Features

- Optimized Design: Ideal for reverse turning operations in tight spaces.

- High-Performance Inserts: Available in various grades for machining materials like steel, aluminum, and titanium.

- Robust Construction: Made from premium materials for durability and reliability.

- Custom Options: Tailored tool holders and inserts to meet specific requirements.

- Perfect for industries requiring precise back-turning operations, such as aerospace, automotive, and medical sectors.

Parting Tool Holder: Our Parting Tool Holders and Inserts are specially designed for CNC sliding head machines, providing reliable performance in parting and grooving operations. These tools are ideal for creating clean, precise cuts in a variety of materials, ensuring high-speed, efficient production.

Key Features

- Precision Cutting: Ensures accurate parting and grooving with minimal vibration.

- High-Quality Inserts: Available in various grades for different material types.

- Durable Construction: Built to withstand high-pressure operations and extend tool life.

- Customizable: Tailored solutions for specific machining requirements.

- Perfect for industries such as automotive, aerospace, and medical device manufacturing.

Grooving Tool Holder: Our Grooving Tool Holders and Inserts for CNC sliding head machines are designed to provide precise and efficient grooving operations. Engineered for high-performance cutting, these tools ensure consistent results and excellent surface finish, even in complex grooving applications.

Key Features

- Precise Grooving: Ensures clean and accurate groove cuts.

- High-Quality Inserts: Available in various grades for different materials.

- Durable Design: Robust construction for extended tool life and reliability.

- Custom Solutions: Tailored tool holders and inserts for specific machining needs.

- Ideal for industries such as automotive, aerospace, and medical device manufacturing.

Thread Tool Holder & custom design threading inserts: Our Thread Tool Holders and Custom Design Threading Inserts are specifically engineered for CNC sliding head machines, delivering precision and high performance for threading operations. These tools ensure smooth, accurate threads with consistent results, even in complex and tight tolerances.

Key Features

- Precision Threading: Ensures accurate thread profiles and smooth finishes.

- Custom Inserts: Tailored inserts for various thread types and material compatibility.

- Durable Construction: Built for long-lasting performance in high-speed machining.

- Versatile: Ideal for internal and external threading applications.

- Perfect for industries such as automotive, aerospace, and medical manufacturing.

Micro Boring and Threading Tools

Our Custom Profile Solid Carbide Micro Boring Bars and Micro Threading Tools are precision-engineered for CNC sliding head machines. These tools are designed for high-accuracy and efficient micro-machining of intricate features, ensuring exceptional finish and tight tolerances. Ideal for small-diameter parts, our tools offer superior durability, wear resistance, and long tool life.

Key Features

- Precision Engineering: Custom profiles for specific applications.

- Solid Carbide Construction: High hardness and wear resistance.

- Versatile: Suitable for micro-boring and threading in various materials.

- Customizable: Tailored to client specifications for unique threading and boring requirements.

- Ideal for industries such as aerospace, medical devices, and electronics.

Hex Broaching Tool

Our Carbide Hex Broaching Tools are designed for precision and durability, ideal for creating hexagonal profiles in high-tolerance components. Crafted from premium carbide, these tools ensure exceptional wear resistance, making them perfect for machining hard materials like stainless steel and titanium.

Key Features

- High dimensional accuracy and surface finish.

- Superior wear resistance and extended tool life.

- Customizable hex sizes to suit various applications.

- Compatible with CNC and conventional machines.

- Ideal for applications in the automotive, aerospace, and medical industries, our carbide hex broaching tools deliver unmatched efficiency and performance.

Knurling Tool Holder

Our Form and Cut Knurling Tool Holders and Tools for CNC sliding head machines are designed for precision knurling operations, delivering high-quality textured surfaces on cylindrical components. These tools are ideal for creating both straight and diamond patterns, offering durability and reliability even in high-volume production environments.

Key Features

- High Precision: Ensures consistent and accurate knurling patterns.

- Durable Construction: Made from premium materials for extended tool life.

- Customizable Tools: Available in various sizes and profiles to suit specific applications.

- Efficient Performance: Reduces cycle time and increases productivity.

- Perfect for industries such as automotive, medical, and aerospace.

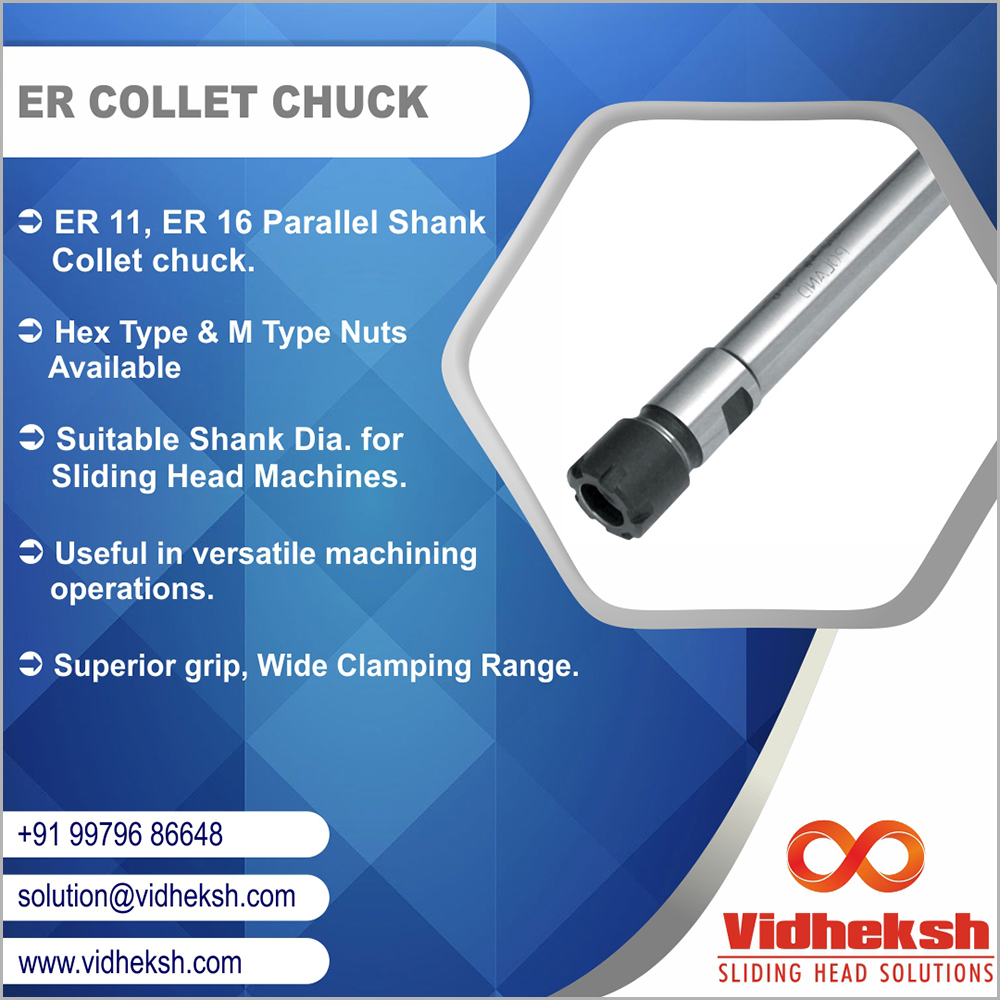

ER Collet Chuck

Our ER Collets and Collet Chucks for CNC sliding head machines are engineered for precision tool holding and efficient machining. Available in single and double-ended configurations, these high-quality collets provide excellent grip, accuracy, and repeatability, ensuring stable performance even during high-speed operations.

Key Features

- Precision Clamping: Ensures accurate tool positioning and secure gripping.

- Durable Construction: Made from hardened steel for extended service life.

- Versatile Application: Compatible with a wide range of tooling and machining tasks.

- Custom Sizes: Available in various sizes for different tool diameters.

- Perfect for industries like aerospace, automotive, and medical device manufacturing.

Toggle / Fingers:

Sliding Head Machine and Bar Feeder Accessories

Our Finger and Toggles for CNC sliding head machines are designed to provide secure and reliable clamping solutions in automated machining processes. These components are ideal for precise work holding and quick part changes, ensuring smooth operation and high productivity in your manufacturing setup.

Key Features

- Precision Clamping: Ensures secure positioning of components during machining.

- Robust Construction: Made from high-strength materials for durability and long life.

- Efficient Operation: Quick and easy part loading and unloading.

- Custom Options: Available in various sizes and configurations to meet specific needs.

- Perfect for industries such as automotive, aerospace, and medical manufacturing.

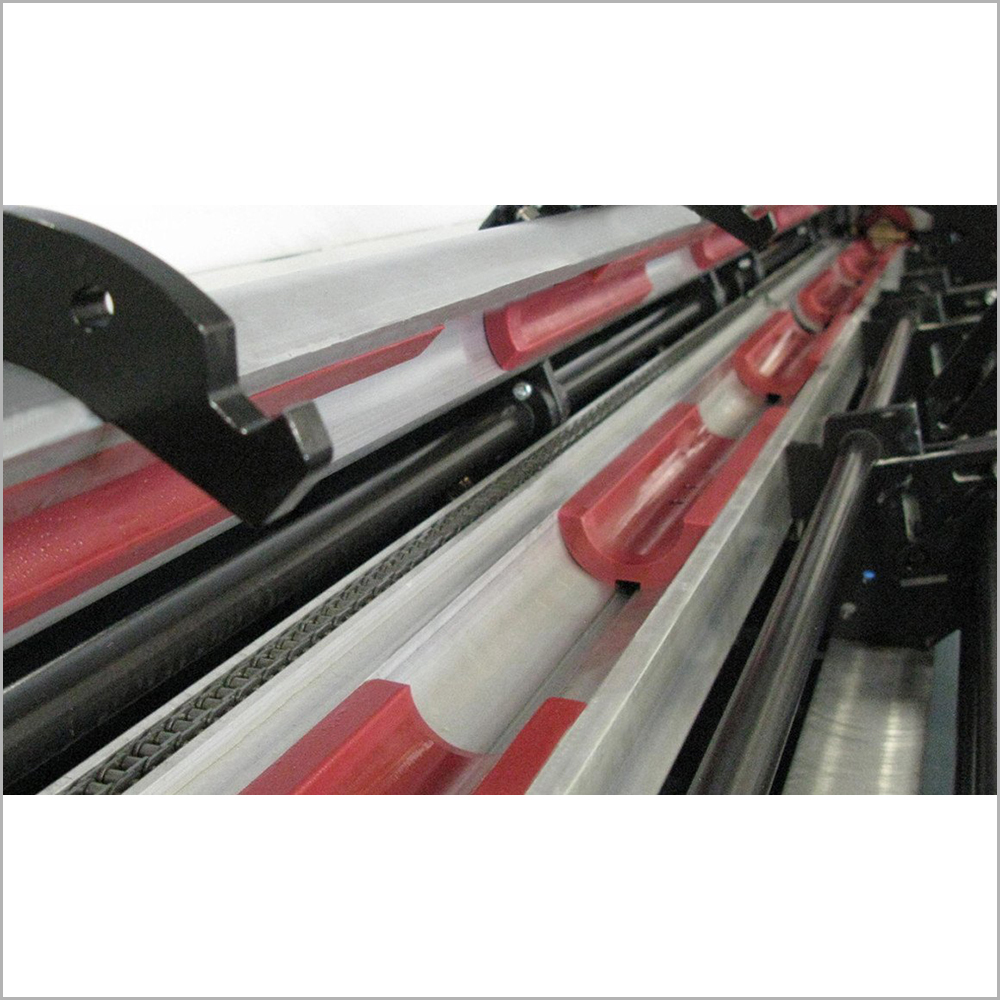

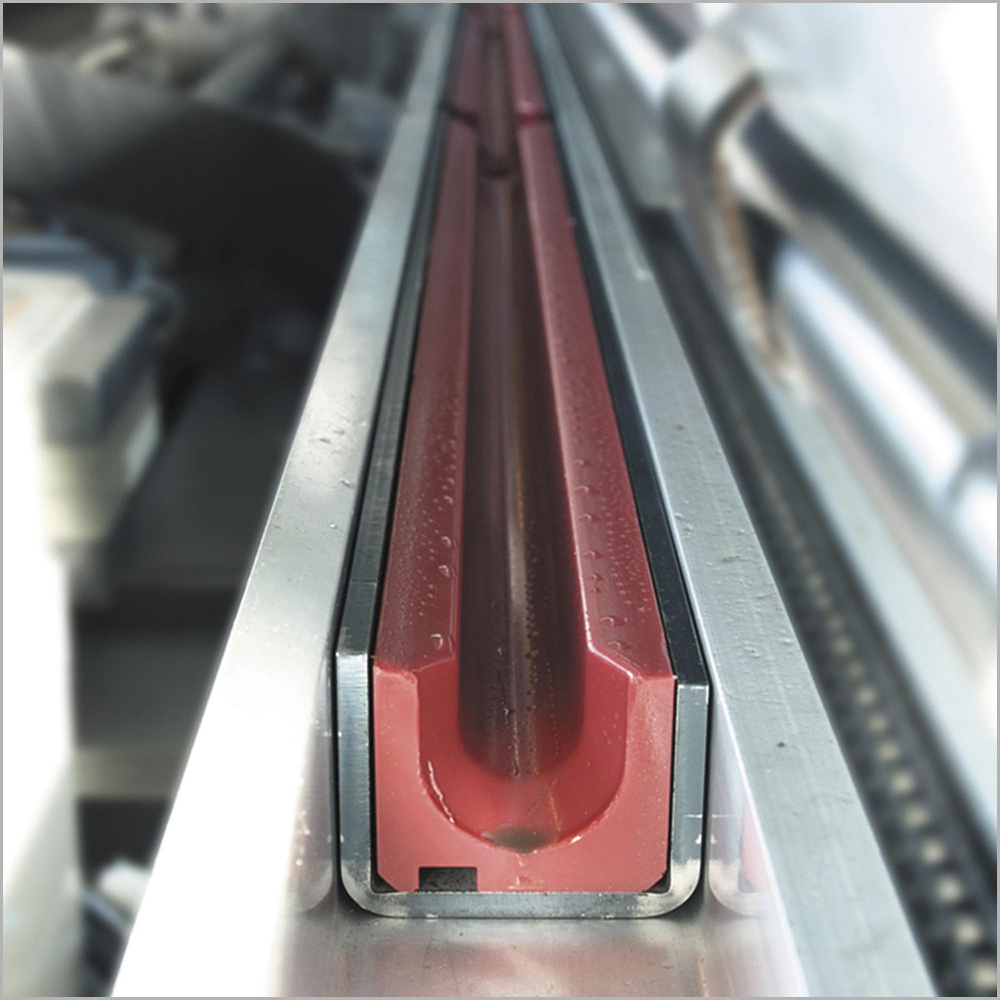

Bar Feeder Channel

Sliding Head Machine and Bar Feeder Accessories

Our Bar Feeder Channels for sliding head CNC machines are designed to optimize precision, efficiency, and reliability in bar feeding operations. Built with high-quality materials, these channels ensure smooth and vibration-free bar movement, enhancing machining accuracy and productivity.

Key Features

- Durable Construction: Resistant to wear and tear for extended service life.

- Vibration Reduction: Ensures consistent feed for high-precision operations.

- Customizable Designs: Available in various sizes to match specific machine requirements.

- Easy Integration: Compatible with leading sliding head machine brands.

- Perfect for high-volume machining tasks, our bar feeder channels are engineered to meet the demands of modern manufacturing environments.

Rotary Joints

Sliding Head Machine and Bar Feeder Accessories

Our Bar Feeder Rotary Joints are designed for CNC sliding head machines, providing efficient and continuous rotation for bar feeding systems. These high-quality rotary joints ensure smooth and reliable transmission of round bars or any raw materials, enhancing machine performance and extending collets, finger chuck and machine life.

Key Features

- Durable Design: Built to withstand high-speed, high-precision operations.

- Easy Installation: Compatible with various CNC sliding head machines.

- Low Maintenance: Designed for long-lasting performance with minimal upkeep.

- Ideal for industries like automotive, aerospace, and precision machining.

Pusher Rod

Sliding Head Machine and Bar Feeder Accessories

Our Pusher Rods for Bar Feeders are designed for seamless and reliable material feeding in CNC sliding head machines. These components ensure smooth movement of the bar stock into the machine for efficient, continuous production, minimizing downtime and enhancing throughput.

Key Features

- Efficient Feeding: Ensures consistent bar movement without jams or interruptions.

- Durable Construction: Made from high-quality materials for long-lasting performance.

- Smooth Operation: Reduces friction and wear for reliable, high-speed machining.

- Customizable: Available in different sizes to fit specific bar feeder models.

- Ideal for industries such as automotive, aerospace, and precision machining.

Flow Meter

Sliding Head Machine and Bar Feeder Accessories

Our Coolant Oil Flow Meters are precision instruments designed for monitoring and controlling coolant oil flow in CNC sliding head machines. These meters ensure optimal coolant delivery, improving tool life, surface finish, and overall machining efficiency.

Key Features

- Precise Measurement: Accurately monitors coolant flow to ensure optimal lubrication.

- Durable Construction: Built to withstand harsh machining environments.

- Easy Installation: Compatible with various CNC sliding head machines.

- Improved Performance: Helps maintain consistent coolant flow for better machining results.

- Ideal for industries requiring high precision, such as aerospace, automotive, and medical devices.

Digital Pressure Sensor

Sliding Head Machine and Bar Feeder Accessories

Our Digital Pressure Sensors for CNC sliding head machines are designed to provide precise monitoring of fluid pressure in machining operations. These sensors offer accurate, real-time pressure readings, ensuring optimal system performance and preventing damage caused by pressure fluctuations.

Key Features

- High Precision: Accurate pressure measurement for efficient operation.

- Durable Design: Built to endure harsh machining environments.

- Digital Display: Easy-to-read digital output for real-time monitoring.

- Reliable Performance: Ensures stable and consistent pressure control.

- Ideal for industries such as automotive, aerospace, and medical device manufacturing.