VMC MACHINE TOOL HOLDERS

Our BT, SK, and HSK Tool Holders for VMC machines are designed to ensure secure, precise, and reliable tool clamping for various machining applications. These holders provide exceptional stability and accuracy, enabling high-speed operations and superior surface finishes.

Key Features

- High Precision: Minimal runout for accurate machining.

- Durable Construction: Made from high-grade materials for long-lasting performance.

- Wide Compatibility: Available in BT, SK, and HSK standards for diverse tooling needs.

- Optimized Performance: Enhances productivity with secure and efficient tool holding.

VMC PULL STUD / RETENSION KNOB FOR TOOL HOLDERS

Our VMC Machine Pull Studs are precision-engineered components designed to secure tool holders to the spindle of vertical machining centers (VMCs). These pull studs ensure a tight, stable connection between the tool holder and the machine, optimizing tool performance and minimizing the risk of tool slippage or runout during machining operations.

Key Features

- Secure Fit: Ensures a stable and precise connection between the tool holder and spindle.

- High-Quality Material: Made from durable steel for long-lasting performance.

- Versatile Compatibility: Available in various sizes for different VMC machine models.

- Compatible Holders: Suitable for BT, HSK, and SK systems.

- Easy Installation: Simple to attach and detach, reducing setup time.

VMC Machine ER Collets

Our ER Collets for VMC machines are designed to securely hold tools and workpieces with precision and stability. These high-quality collets are ideal for a wide range of machining applications, ensuring accurate tool alignment and superior gripping force. Made from durable materials, they provide reliable performance, extended tool life, and quick, easy changes during setup.

Key Features

- High Precision: Ensures secure and accurate tool clamping.

- Durable Construction: Made from high-strength materials for long-lasting performance.

- Versatile Use: Compatible with various tools and materials.

- Quick Tool Change: Fast setup and reduced downtime.

VMC Machine ER Collet Nut

Our ER Collet Lock Nuts (M Type and Hex Type) are designed to securely fasten ER collets in VMC machines. These lock nuts ensure tight clamping and prevent the collet from loosening during high-speed machining operations. Available in M-type and Hex-type designs, they offer ease of installation and reliable performance for precise tool holding.

Key Features

- High Clamping Force: Ensures secure tool positioning.

- Durable Materials: Constructed for long-lasting use.

- Easy to Install: Fast and simple tool change.

- Versatile Design: Compatible with both M-type and Hex-type collets.

VMC CLAMPING KIT

Our VMC Clamping Kits are designed to securely fix workpieces on vertical machining centers, ensuring stability and precision during machining. These kits include a range of clamping components that are versatile, easy to set up, and suitable for various workpiece sizes and shapes.

Key Features

- Comprehensive Kit: Includes clamps, studs, T-nuts, and other essential components.

- Durable Material: Made from high-strength materials for extended use.

- Easy Setup: Quick and efficient clamping system.

- Enhanced Stability: Ensures consistent and accurate machining results.

VMC Tool Clamping Fixture

Our VMC Tool Clamping Fixtures are precision-engineered to securely hold tools and workpieces on vertical machining centers. These fixtures are designed to enhance accuracy, reduce setup times, and support complex machining operations by providing reliable and stable clamping solutions.

Key Features

- Precision Clamping: Ensures stability and accurate positioning for high-quality machining.

- Durable Build: Made from premium materials for long-lasting performance.

- Customizable Options: Available in various configurations to suit diverse machining needs.

- Improved Efficiency: Reduces downtime with quick and easy setup

Universal Magnet Stand

Our Universal Magnet Stand is designed for secure, flexible positioning of measuring instruments, gauges, and tools in a variety of applications. The strong magnetic base ensures stable attachment to metal surfaces, providing precise adjustments and reliable support during operations.

Key Features

- Powerful Magnetic Base: Strong hold on metal surfaces for stability.

- Adjustable Arm: Allows for flexible positioning of tools and instruments.

- Durable Build: Constructed from high-quality materials for long-term reliability.

- Versatile Use: Suitable for measurement, inspection, and various industrial applications.

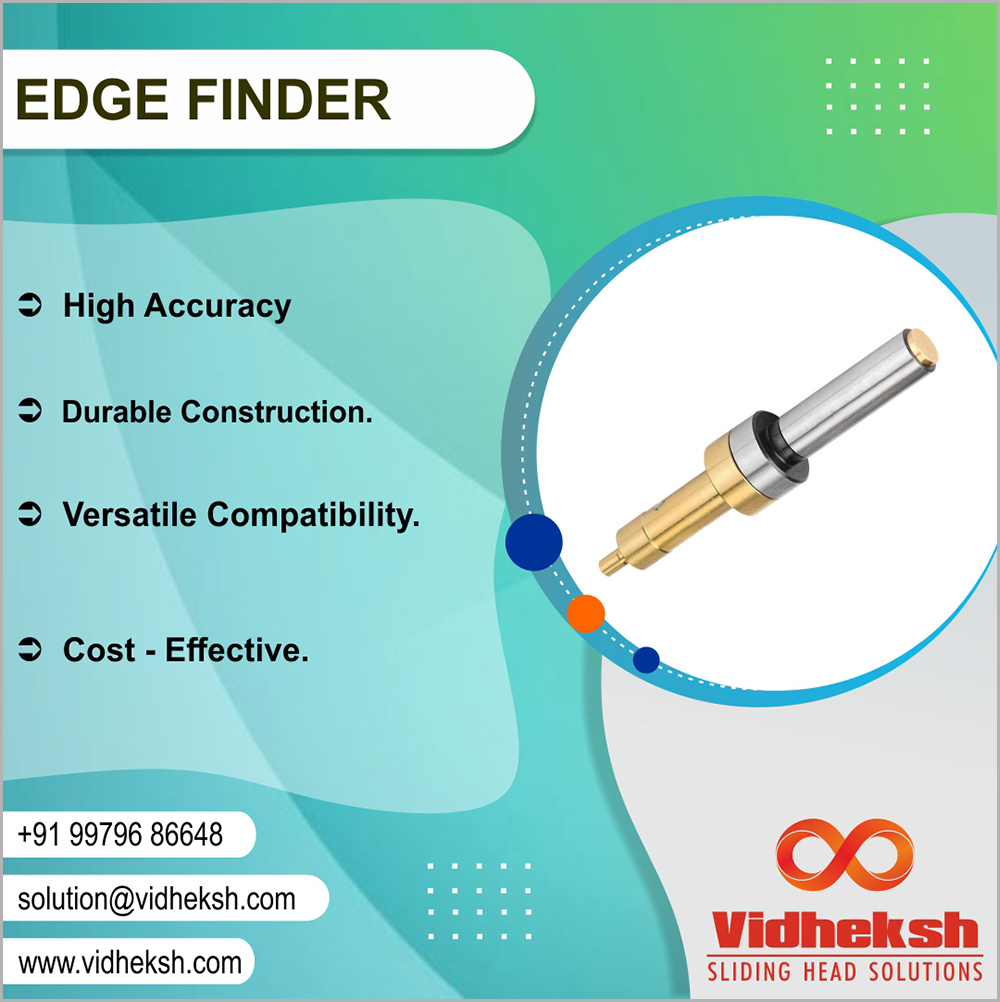

EDGE FINDER

Our Mechanical, Electrical, and Optical Edge Finders for VMC machines are precision tools designed to quickly and accurately locate the edges of a workpiece. These edge finders improve setup time and machining accuracy, ensuring consistent results in high-precision applications.

Key Features

- Mechanical Edge Finders: Simple and reliable, providing tactile feedback.

- Electrical Edge Finders: Enhanced precision with electronic signal detection.

- Optical Edge Finders: Non-contact measurement for delicate or intricate workpieces.

- Versatile Use: Ideal for locating edges, holes, and features on various materials.

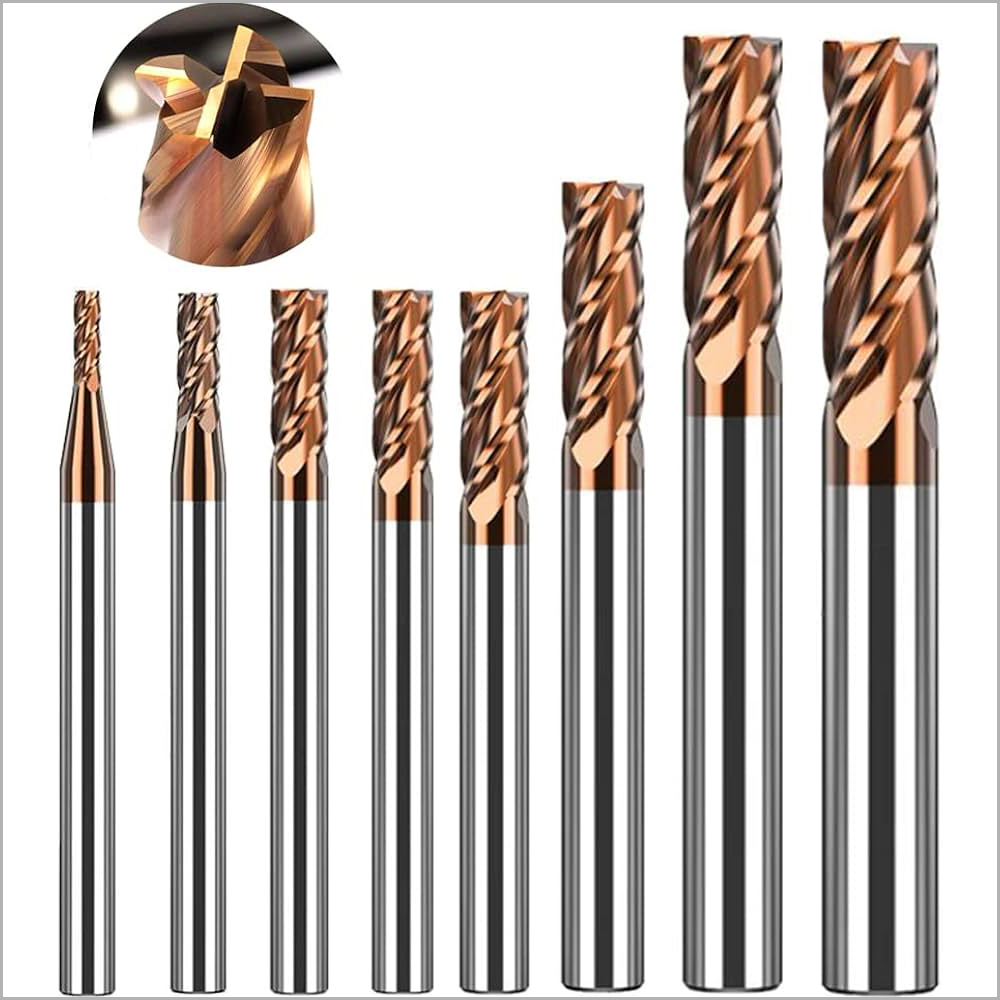

SOLID CARBIDE END MILL CUTTERS

Our Solid Carbide End Mill Cutters are engineered for high-performance machining in VMC machines. Designed to offer exceptional durability, precision, and heat resistance, these cutters provide superior cutting efficiency and long tool life. Ideal for a wide range of materials, they deliver smooth finishes and high-quality results in both roughing and finishing operations.

Key Features

- High Wear Resistance: Made from premium solid carbide for extended tool life.

- Precision Cutting: Provides smooth finishes and accurate results.

- Versatile Use: Suitable for a variety of materials, including metals and alloys.

- Enhanced Efficiency: Reduces cycle times and improves machining performance.

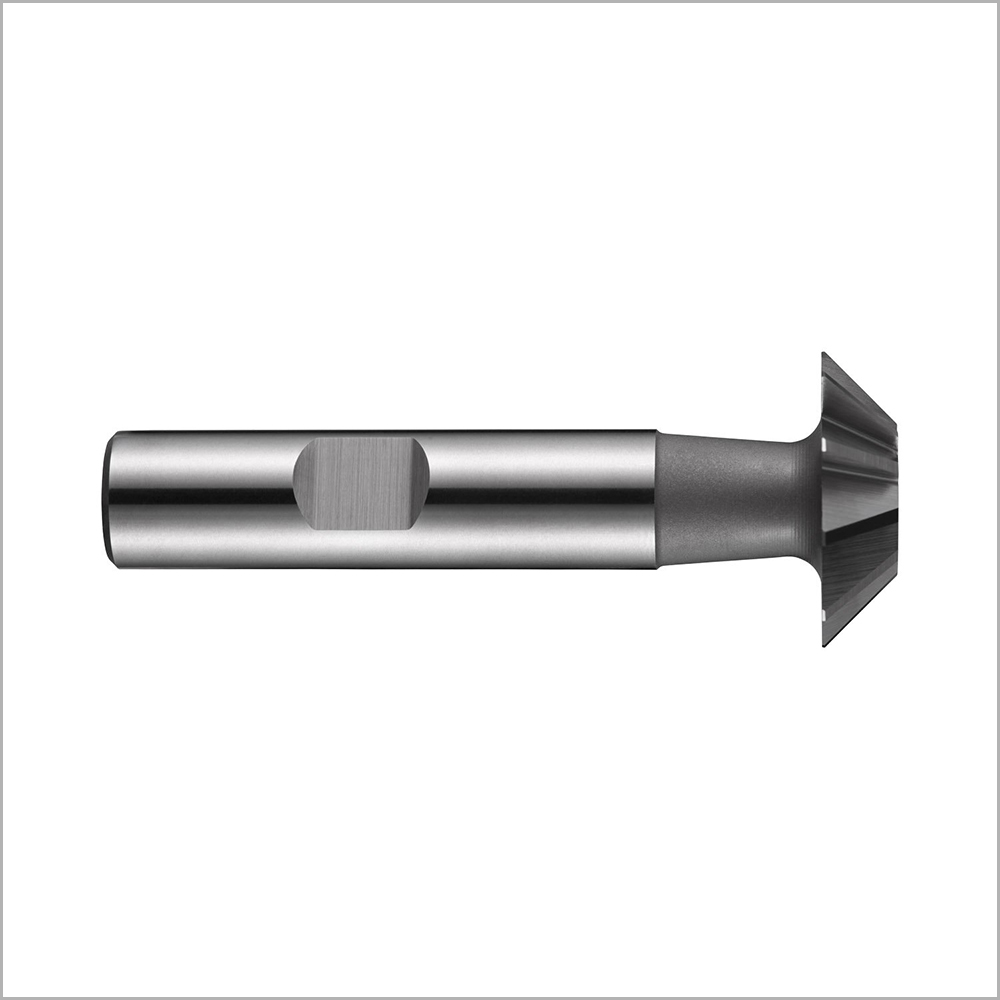

SOLID CARBIDE TAPER END MILL CUTTERS

Our Solid Carbide Taper End Mill Cutters are designed for precise and efficient machining of complex shapes and angled surfaces. Made from high-quality solid carbide, these cutters provide excellent durability, heat resistance, and cutting performance. They are ideal for both roughing and finishing operations on a variety of materials, ensuring superior surface finishes and extended tool life.

Key Features

- Precision Taper Design: Ideal for angled cuts and precise surface finishing.

- High Wear Resistance: Premium carbide construction for durability and long life.

- Versatile Application: Suitable for a range of materials, including tough alloys.

- Enhanced Cutting Efficiency: Delivers smooth finishes and reduces machining time.

Solid Carbide Ball Nose Cutters

Our Solid Carbide Ball Nose Cutters are designed for precision machining of complex 3D contours, slots, and curves. These high-performance tools are ideal for creating smooth, rounded profiles and achieving high-quality surface finishes in both roughing and finishing operations. Made from durable solid carbide, they offer excellent wear resistance and heat tolerance, ensuring longer tool life and consistent performance.

Key Features

- Precision Ball Nose Design: Ideal for 3D contouring and surface finishing.

- High Wear Resistance: Solid carbide construction for longer tool life.

- Smooth Surface Finish: Delivers high-quality finishes for intricate shapes.

- Versatile Application: Suitable for a wide range of materials, including alloys.

Solid Carbide Taper Thread Mill Cutter

Our Solid Carbide Taper Thread Milling Cutters are designed for precision thread milling, especially for tapered threads. These high-performance tools provide exceptional accuracy and finish while reducing cycle time. Manufactured from premium solid carbide, they offer superior wear resistance and heat tolerance, ensuring longer tool life and stable performance.

Key Features

- Tapered Thread Design: Ideal for producing tapered threads with high precision.

- Durable Carbide Construction: Extended tool life and high wear resistance.

- Smooth Finish: Delivers consistent and high-quality thread finishes.

- Versatile Use: Suitable for a wide range of materials and applications.

- Versatile Application: Suitable for a wide range of materials, including alloys.

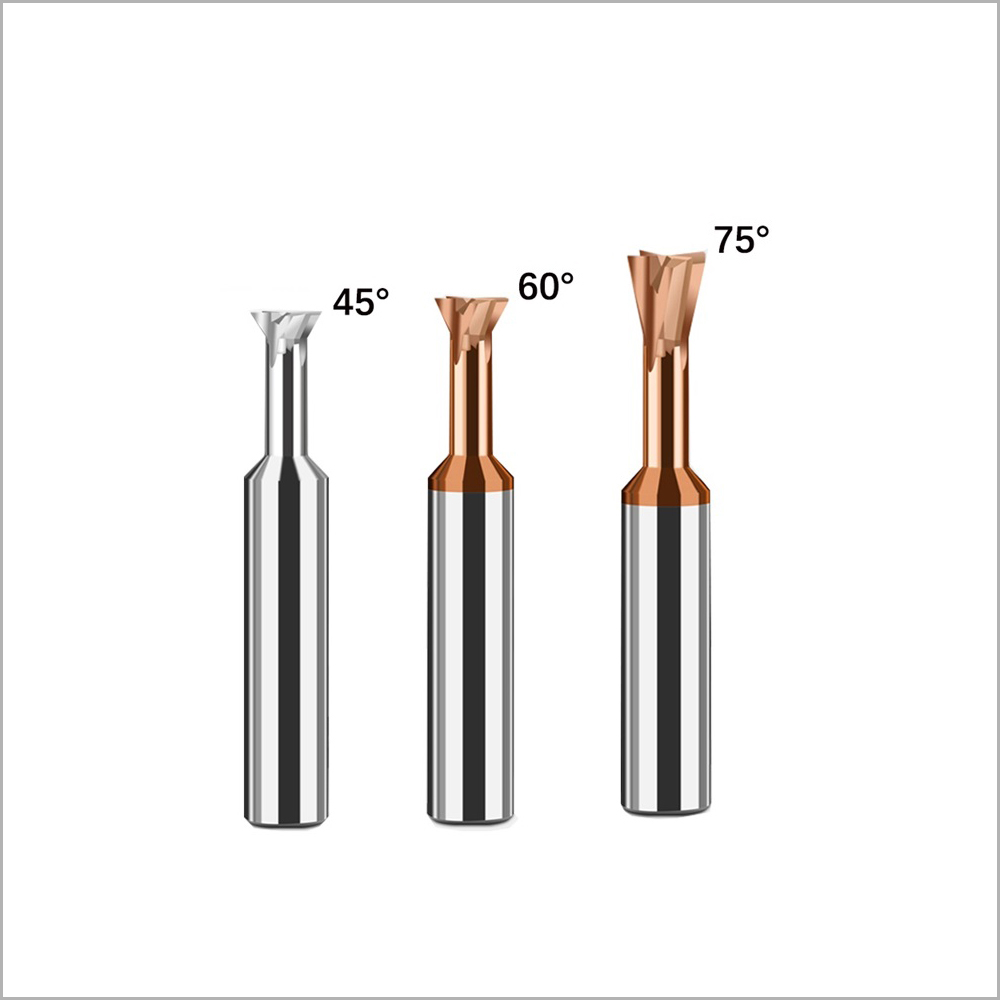

Solid Carbide Dovetail Cutter

Our Solid Carbide Custom Design Dovetail Cutters are engineered to provide precise and efficient cutting for dovetail joints and other angled profiles. Tailored to meet your specific machining needs, these custom cutters offer exceptional strength, high wear resistance, and superior performance on VMC machines. Perfect for producing intricate shapes and achieving fine finishes with tight tolerances.

Key Features

- Custom Design: Tailored to your specific application requirements.

- High Precision: Provides accurate dovetail cuts and profiles.

- Durable Construction: Solid carbide for extended tool life.

- Versatile Application: Ideal for a variety of materials and angles.

Z Axis Zero Setter

Our Z Axis Zero Setters (available in Digital and Dial types) are precision tools designed for quick and accurate setting of the Z-axis position on VMC machines. These setters ensure accurate workpiece alignment, improving efficiency and reducing setup time. Whether you choose the digital version for easy readouts or the dial type for manual precision, both offer high reliability and ease of use.

Key Features

- Precise Z-Axis Setting: Ensures accurate positioning for machining.

- Digital and Dial Types: Choose based on preference for quick readout or manual control.

- Durable and Reliable: High-quality construction for long-lasting performance