Gun Drill Machine Oil Filter Bag

Our Gun Drill Machine Oil Filters are designed to maintain optimal oil quality and protect critical machine components during drilling operations. These filters effectively remove contaminants and debris, ensuring smooth and efficient gun drilling processes while extending the life of your machinery.

Key Features

- High Filtration Efficiency: Removes fine particles and impurities.

- Durable Construction: Withstands high pressure and temperatures.

- Improved Performance: Maintains consistent oil flow for precise operations.

- Ideal for ensuring reliability and longevity in gun drilling applications.

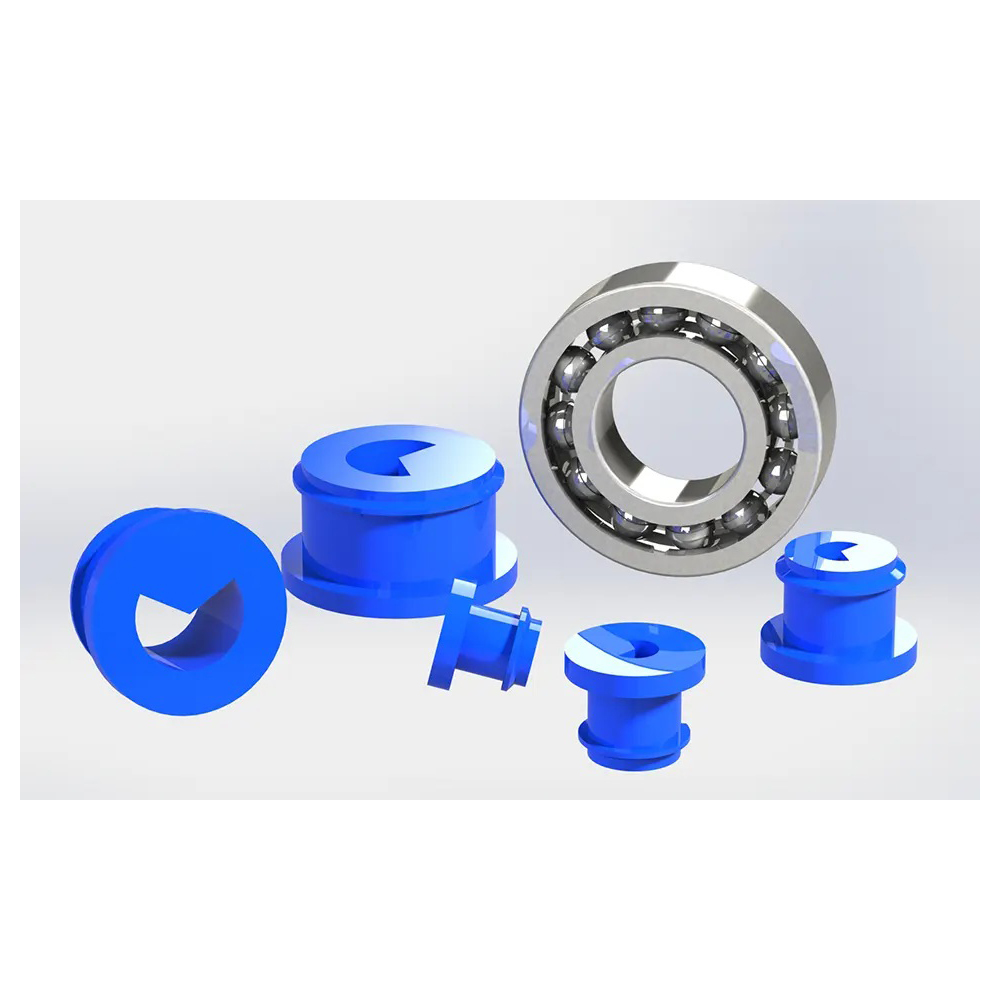

Gun Drill Machine Whip Guide / Drill Guide

Our Whip Guides/Drill Guides are specifically designed to provide optimal gun drill support with bearing for gun drilling machines. Crafted from high-grade polyurethane (PU) material, they ensure durability, flexibility, and excellent performance in guiding gun drill tools with precision.

Key Features

- Enhanced Tool Support: Stabilizes and guides gun drill tools for accurate operations.

- Premium PU Material: Resistant to wear and tear, ensuring long service life.

- Improved Machine Performance: Reduces vibration and deflection during drilling.

- Ideal for achieving precision and consistency in gun drilling processes.

Chip Deflector

Our Chip Deflector is specifically designed for gun drill machines to enhance efficiency and precision by effectively managing chip evacuation during the drilling process. This robust and durable accessory ensures smooth machining operations while minimizing tool wear and workpiece damage.

Key Features

- Durable Construction: Made from high-quality, wear-resistant materials.

- Efficient Chip Evacuation: Prevents clogging and ensures smooth operations.

- Precision Fit: Designed for compatibility with various gun drill machine models.

- Enhanced Cooling: Promotes effective coolant flow to reduce heat and tool wear.

- Easy Installation: Simple design for quick setup and maintenance.

- Improved Tool Life: Reduces vibration and minimizes drill damage.

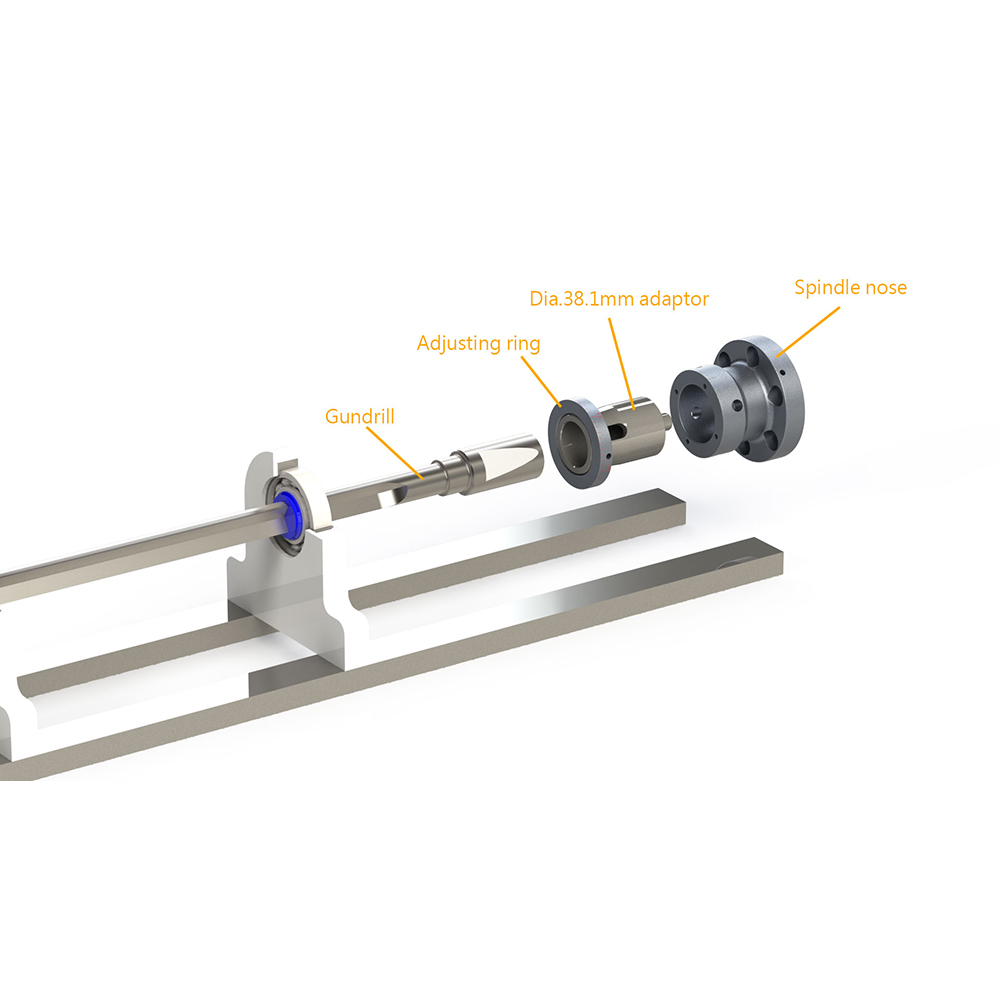

Guide Bush

Our Guide Bush is a critical component designed to ensure precision and stability in gun drilling operations. It serves as a support system for the gun drill, minimizing deflection, enhancing accuracy, and promoting smooth operation during high-performance drilling tasks.

Key Features

- High Precision: Accurately aligns the drill for superior hole quality and consistency.

- Durable Construction: Manufactured from premium materials like tool steel, or hardened alloys for enhanced durability and extended life.

- Wear and Heat Resistance: Designed to withstand high temperatures and abrasive conditions during high-speed machining.

- Customizable Options: Available in various sizes, materials, and configurations to meet specific machine and application needs.

- Enhanced Drill Support: Reduces vibration and deflection, ensuring smooth and stable drilling operations.

- Improved Tool Life: Minimizes wear on the drill tool, extending its lifespan and reducing operational costs.

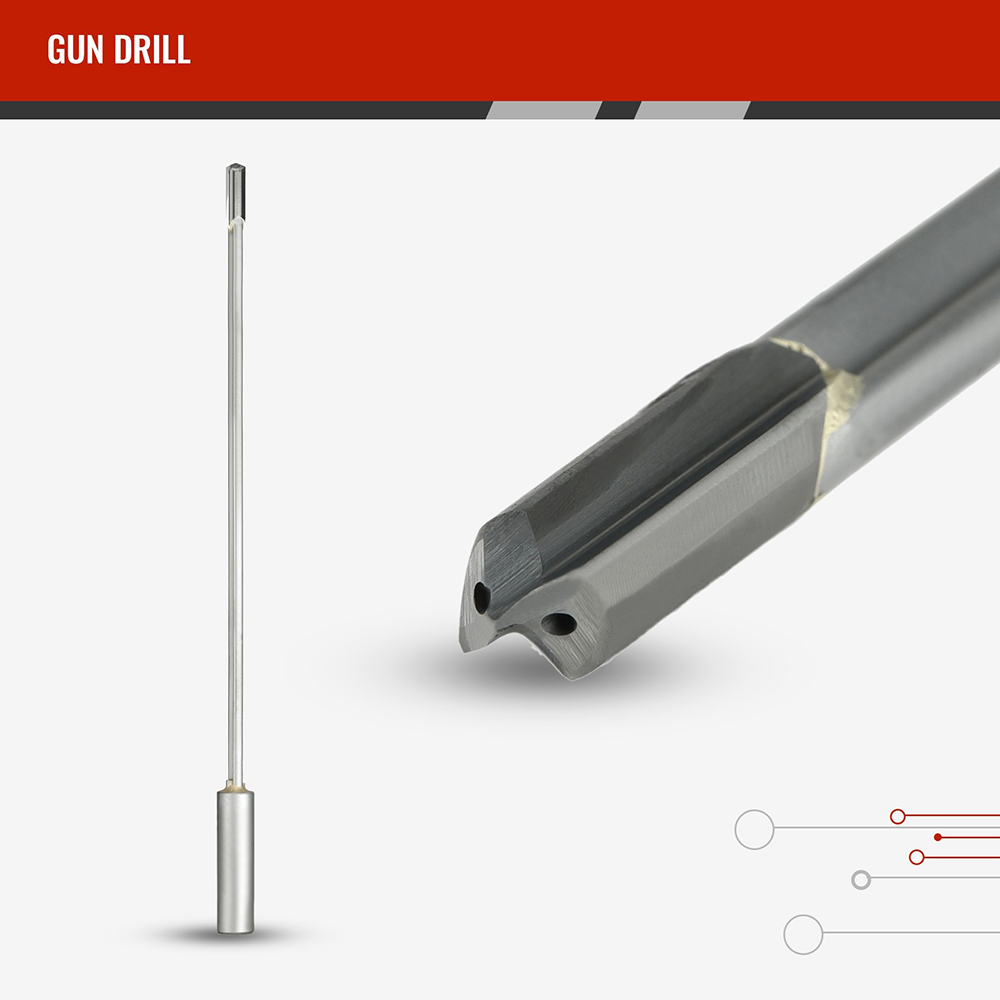

Gun Drill Tool

Our Carbide Gun Drilling Tools are precision-engineered to meet the demands of deep hole drilling with unmatched accuracy and durability. These tools are ideal for industries requiring high precision, excellent surface finish, and efficient chip evacuation in a variety of materials.

Key Features

- Premium Carbide Material: Manufactured using high-quality carbide for maximum hardness, durability, and wear resistance.

- Precision Drilling: Achieves tight tolerances and superior accuracy, ensuring consistent performance in deep hole drilling.

- Advanced Flute Design: Optimized for efficient chip evacuation, preventing clogging and ensuring smooth operations.

- Versatility: Suitable for a range of materials, including steel, cast iron, aluminum, and non-ferrous alloys.

- Customizable Options: Available in various diameters, lengths, and tip geometries to suit specific application requirements.

- Extended Tool Life: Designed to minimize wear and maximize operational efficiency, reducing overall tooling costs.