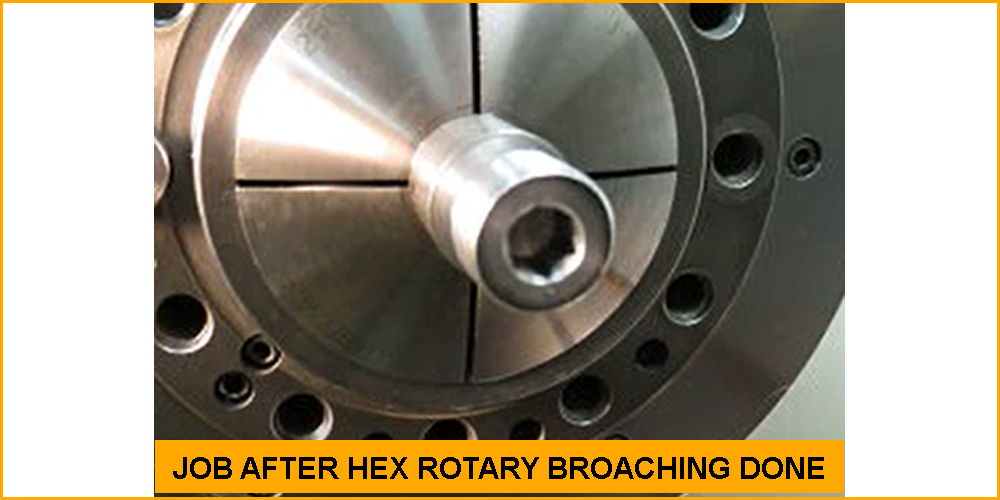

Hexagonal Holes Made Easy (and Beautiful!) in Stainless Steel: Our Rototech CNC Rotary Broaching Trial Success!

At Vidheksh Sliding Head Solutions, we're constantly exploring innovative tooling solutions to help our clients tackle challenging machining tasks with greater efficiency and precision. Recently, we had the privilege of conducting a trial of a CNC Rotary Broaching Tool Holder for hexagonal broaching in stainless steel at one of our esteemed client's facilities in Nasik (India) – and the results have been truly outstanding!

Working with stainless steel (SS304 grade) often presents unique challenges, especially when it comes to internal features like hexagonal holes. Traditional methods can be time-consuming, require specialized machinery, and sometimes struggle to achieve the desired finish and dimensional accuracy. This is where the power of rotary broaching comes into play, and our recent trial has emphatically demonstrated its capabilities.

The Challenge: Efficient and High-Quality Hexagonal Broaching in SS

Our client was facing the need to produce hexagonal internal features in stainless steel components, demanding both precise dimensions and a high-quality surface finish. They were seeking a more efficient and reliable alternative to their existing methods. This presented the perfect opportunity to showcase the potential of a CNC rotary broaching tool holder.

The Solution: Unleashing the Power of Rotary Broaching on their CNC

We introduced them to our Rototech CNC rotary broaching tool holder, designed for seamless integration with their existing CNC Turning Machine. The beauty of rotary broaching lies in its ability to create internal forms using the existing spindle rotation of the CNC machine, eliminating the need for specialized broaching machines.

The Results: A Trifecta of Success!

The trial yielded impressive results across the board, leaving our client highly satisfied:

- Exceptional Performance: The rotary broaching tool effortlessly created precise and accurate hexagonal holes in the stainless-steel material. The process was smooth, consistent, and demonstrated excellent stability.

- Impressive Tool Life: We closely monitored the tool wear throughout the trial and were delighted by the longevity of the rotary broaching tool. It maintained its cutting edge effectively, promising a significant reduction in tooling costs over time.

- Superior Product Outcomes & Finishing: The finished hexagonal features exhibited excellent dimensional accuracy and a remarkably clean and smooth surface finish. The client was particularly impressed with the quality achieved, meeting their stringent requirements.

Client Satisfaction: The Ultimate Validation

The most rewarding outcome of the trial was the high level of satisfaction expressed by our client. They were thrilled with the performance of the CNC rotary broaching tool holder, noting its ease of integration, the quality of the finished parts, and the potential for significant time and cost savings in their production process.

The Advantages of CNC Rotary Broaching for Internal Hexagons (and More!):

This successful trial underscores the numerous benefits of utilizing CNC rotary broaching tool holders for creating internal hexagonal features, especially in challenging materials like stainless steel:

- Cost-Effective Solution: Eliminates the need for dedicated broaching machines, leveraging the capabilities of existing CNC equipment.

- Increased Efficiency: Offers a faster and more streamlined approach compared to traditional methods.

- Excellent Accuracy and Repeatability: Ensures consistent and precise internal forms.

- Superior Surface Finish: Achieves a high-quality finish, often eliminating the need for secondary operations.

- Versatile Application: Suitable for a range of materials, including stainless steel, and various internal forms beyond hexagons (e.g., Square, Torx).

Looking Towards Enhanced Machining Capabilities:

The positive outcome of this CNC rotary broaching tool holder trial in Nasik (India) highlights the potential for manufacturers to significantly enhance their internal machining capabilities. By embracing innovative tooling solutions like rotary broaching, businesses can achieve improved efficiency, higher quality, and greater cost-effectiveness, even when working with demanding materials like stainless steel.

Are you facing challenges with internal form machining, particularly in stainless steel? Contact us today to explore how CNC rotary broaching tool holders can revolutionize your production process and deliver exceptional results!